New technologies and new solutions require an efficient organizational model oriented towards the highest quality and safety of products, in full compliance with environmental protection.

The international medical device market in which Plastod has always operated is constantly evolving and requires continuous updates n and requires continuous updates

Plastod’s Business Management System, which includes all phases of design, production and control of medical devices, is certified according to the international standards ISO 9001 and ISO 13485 by a Notified Body accredited on a European scale and recognized internationally.

Plastod considers the safety aspect of the product to be strategic. The high quality of Plastod products is supported by the continuous updating of technical and regulatory skills and a deep knowledge of the specific clinical use of the device and its possible evolutions.

In additon, Plastod is frequently audited by most important European Notified Bodies and by Local Authorities of European and extra-European countries where Plastod’s products are registered

Sistematic process control

The design and production take place entirely at the Calderara di Reno site, where both the production lines and the production departments are subjected to strict validations. The production environments have controlled particle and microbial contamination (clean rooms) and are ISO 8 classified according to current standards, ensuring very low levels of contamination of the final product.

Plastod carries out full control of its production procedures and processes carried out by qualified external suppliers, such as sterilization by irradiation and ethylene oxide. Even the suppliers of the materials used for the production are subject to strict surveillance, which ensures the flawless execution of the product and total safety for the end user.

The systematic control of materials and products guarantees constant and high quality right from the procurement

Plastod products are registered in Europe and in many countries around the world. Plastod has therefore always been subject to compliance checks by the major Notified Bodies and Competent Authorities in Europe and beyond. Thanks to the knowledge of European and international regulatory requirements, Plastod is able to manage any European and international product certification procedure

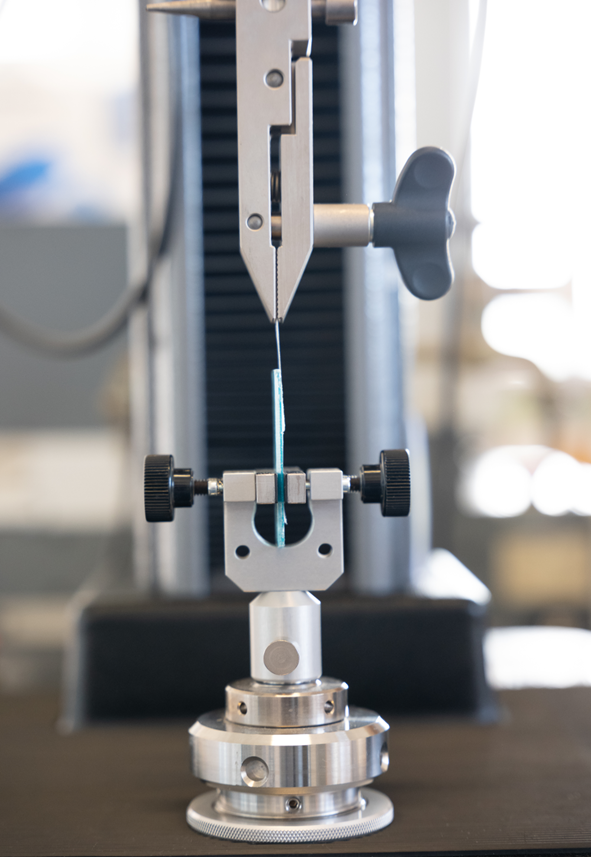

Intruments of Control

In order to certify the conformity of medical devices from the design phase to the final product, Plastod can boast the support of an Internal Laboratory with high technical and chemical-biological skills and an accurate analysis instrumentation, periodically subjected to calibration.

For specialized tests and complex experimental studies mainly related to specific design phases, Plastod has also built a network of qualified and accredited External Laboratories, for defining test protocols and evaluating the test results. Plastod also uses expert consultants in the clinical application field to carry out the necessary clinical risk-benefit assessments of the medical devices for which it is responsible.

Risk Classes

The in-depth knowledge of the European legislative and regulatory aspects in force has allowed Plastod to be responsible for the design and manufacture of medical devices belonging to all risk classes, from class I to class III.

Our Certifications

Plastod has reached following Certifications